An Overview of Supply Chain

Businesses selecting local suppliers can not only fulfill their social responsibility to the community but also reduce the environmental impact resulting from transportation and distribution over long distances. In 2023, more than 94% of GIGABYTEʼs first-tier suppliers were located in Asia, of which 92% were in the areas where our main manufacturing bases are situated. GIGABYTE adheres to local procurement in order to maintain productivity and continuity of operations as well as improve local economic development.

Local Procurement Rate

The local procurement rates at all of GIGABYTEʼs main manufacturing locations (i.e., Nanping, Dongguan, and Ningbo) have exceeded 75% in recent years. In 2022, the local procurement rate was 81.25%.

Local Procurement Rate in the Past 5 Years

[Note 1] Local:The sites where materials are produced are in the areas where GIGABYTEʼs main manufacturing bases are located.

[Note 2] Procurement amount:calculate based on the purchase amount of the year.

Supply Chain Management Policy and Risk Management

In 2018, GIGABYTE officially issued the “GIGABYTE Sustainable Procurement Guidelines” which applies to the Headquarters, Nanping Factory, two factories in China, and the subsidiaries with substantial influence in Taiwan. We reference with the “Code of Conduct for Responsible Business Alliance” issued by the Responsible Business Alliance (RBA) as the highest guiding principle. 4 major management aspects (including 15 sub-goals) and 4 zero tolerance regulations are set to assess the risk of a supplier. When selecting suppliers, other than the basic requirements like quality, delivery, service, cost, etc., we also conduct investigations and regulations for environmental management systems, occupational safety and health systems, corporate social responsibility, hazardous substances, etc., to ensure that the chosen suppliers are in compliance with sustainable procurement standards.

4 Management

Product quality, production and manufacturing ability, service, deliver time, price.

ISO 14001, legal compliance, environment management measures.

GIGABYTE Hazardous Substances Management, international standards and regulations of chemicals management

Sustainable supply chain evaluation management system, labor human right, conflict minerals, ISO 45001, corporate ethics.

4 Zero Tolerance Regulations

- Child labor

- Forced labor / prison labor

Discharge of untreated toxic and hazardous substances or materials

Behaviors that cause immediate injury to employees

Download the GIGABYTE Sustainable Procurement Guidelines

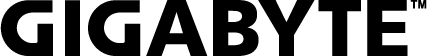

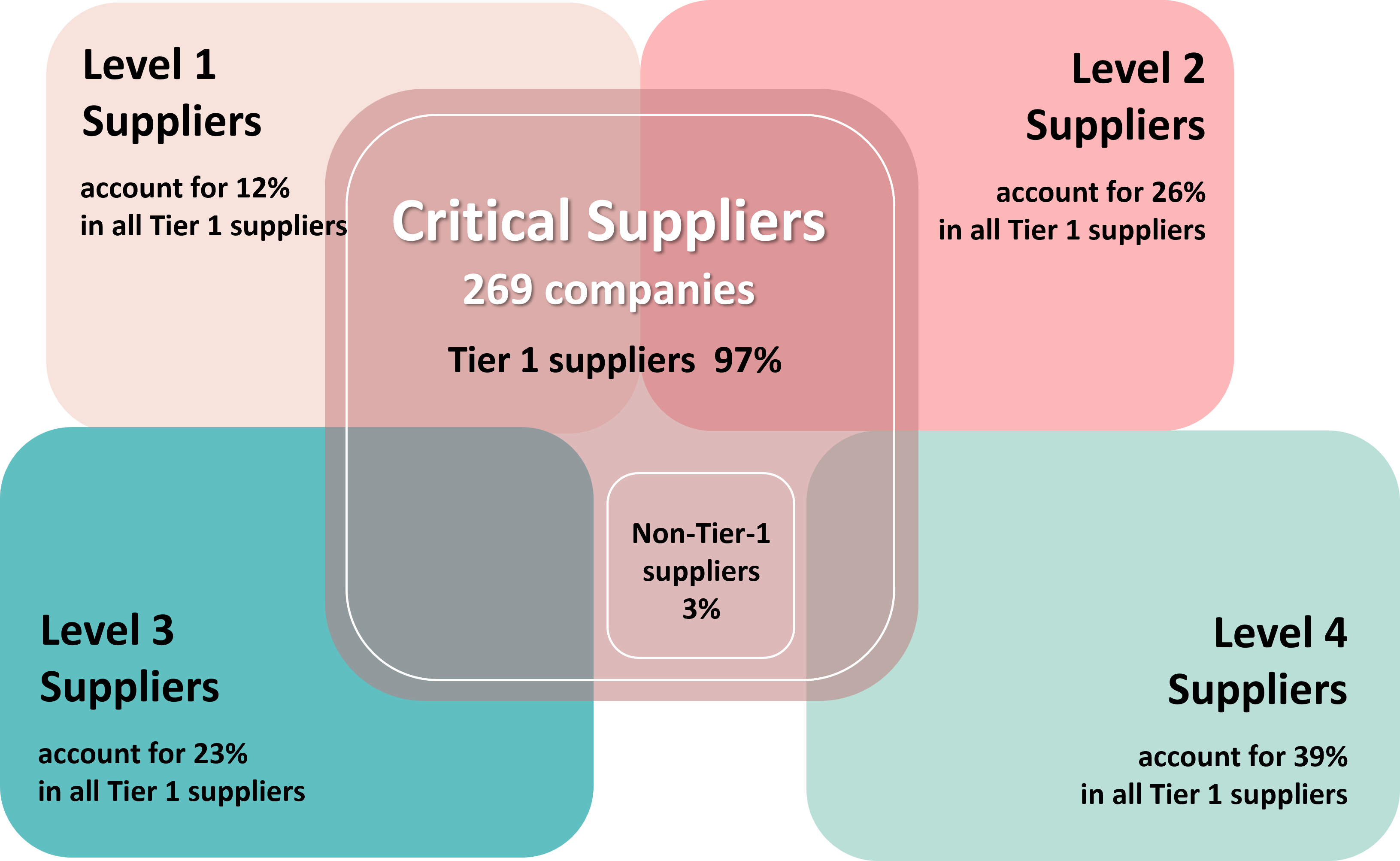

Tiered Supplier Management

GIGABYTE adopts tiered management for existing and new suppliers through evaluation in accordance with the “Supplier Quality Management Practices”. After several internal discussions since 2022, the tiered supplier management system has finally incorporated into the Enterprise Resource Planning (ERP) system. In addition to the existing criteria such as supplier contracts (CMRT, RBA) and material rating (quality, delivery, cost, and service), it also integrates the supplier sustainability assessment system which has been promoted and implemented since 2012. The new system enables the grading and rating to fully reflect the overall sustainability performance of GIGABYTEʼs suppliers. Moreover, a high CSR-related risk assessment is conducted quarterly, and suppliers rated as D-level will be weeded out. The strategic assessment of suppliersʼ sustainability performance provides assurance of the quality and stability of the suppliers and reduces supply chain risks.

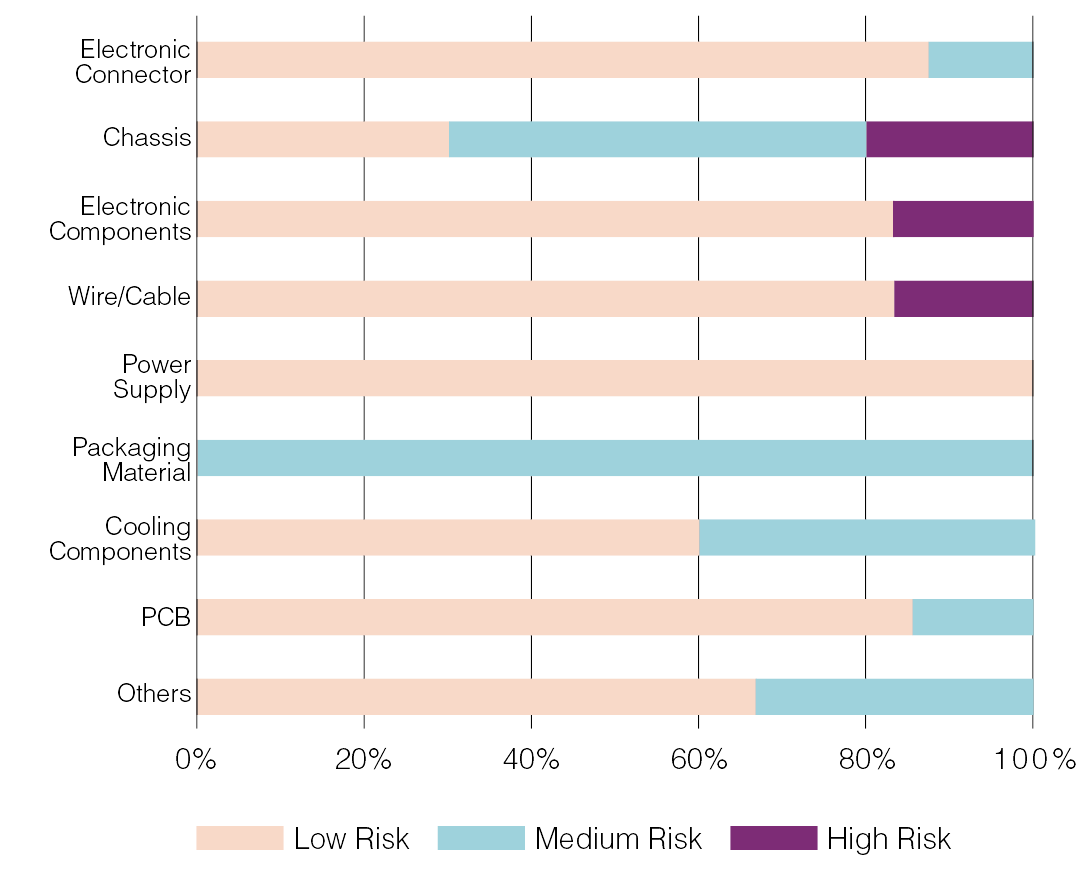

In 2023, GIGABYTE audited 58 suppliers for RoHS, quality, and CSR. The audit identified 14 suppliers with moderate risk and 5 suppliers with high risk, with quality system audits being the most common problem. The suppliers were put on a registry by GIGABYTE, and 1 vendor had improved and been re-rated as low risk after the repeat audit. We will continue to track the situation with these suppliers in the future. In terms of CSR, suppliers were assessed against the Responsible Business Alliance (RBA) Code of Conduct in 2023 and around 90% of cases were good (scored above 85). The overall average score was 94.39. We will continue to promote related initiatives and projects in the future so that we can lead our supply chain partners in embracing sustainability.

Audit Result of Quality System / RoHS

Audit Result of Supplier CSR Performance

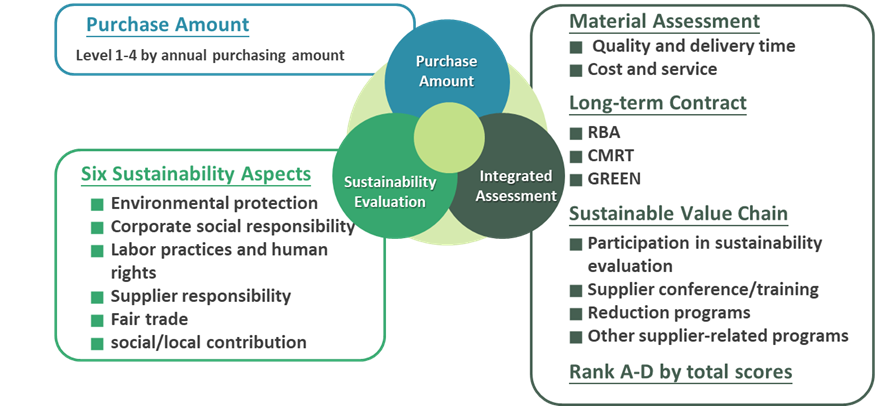

High CSR Risk Assessment Mechanism

Under the new tiered supplier management system , GIGABYTE identifies critical suppliers by looking at indicators such as procurement amount and key materials, and a quarterly CSR risk assessment is conducted for critical suppliers. The assessment covers 4 aspects: society, environment, governance, and commerciality. We enhance the management of suppliers with substantial impacts along the supply chain by investigating whether they have been fined for labor, environment, financial transactions, and conflict minerals violations. The matrix also considers corporate governance evaluation, ESG disclosure scope, and positive and negative media coverage. A report on high-risk suppliers is then provided to relevant personnel within each BU to improve their supplier management.

The Ratio of 1-tier Suppliers by Level and the Composition of Critical Suppliers in 2023

- Home

- Innovation Management

- The Guanxi Blue Zone

- The Ocean is Our Home

- From the Chairman

- Commitment to CSR

- Stakeholder Engagement

- Material Topics

- SDGs

- Corporate Organization

- Code of Conduct

- Information Security & Privacy

- Risk Management

- Supply Chain Management

- Tetralogy of Supply Chain Engagement

- Conflict Mineral

- Environmental Management Policy

- Climate Action

- Eco-friendly Product

- Extended Product Responsibility

- Circular Economy

- Green Action

- Sustainability/Environmental Education

- Green Activities

- Working Holiday

- Corporate Volunteering

- Go Green Taiwan

- Make Earth Green Again

- Tree Map

- Overview/Core Concept

- Rooftop Farm

- Ecology Photo Competition

- Sustainability-related Certification

- Human Resource Structure

- Talent Management

- Human Rights Management

- Talent Cultivation and Development

- Occupational Safety

- Health Care

- Upgrade Your Life

- Social Inclusion

- CSR Milestone

- Economic Aspect

- Environmental Aspect

- Social Aspect

- CSR Report