Occupational Safety and Health Management Plan

GIGABYTE operating locations that have obtained ISO 45001:2018 OHS management system certification include the Headquarters, Taoyuan Nanping Factory, China-Dongguan Factory, and China-Ningbo Factory. The management scope includes employees, on-site contractors, visitors, and any personnel near the workplace that may affect organizational activities. Although the subsidiaries Giga Computing, Bestyield International, G-Style, Cloudmatrix, and Selita Precision, as well as the sub-subsidiary GIGAIPC are not certified yet, GIGABYTE still adopts management measures aligned with the principles of ISO 45001:2018 to strengthen workplace health and safety practices. Please visit Resource Hub to review the certificates.

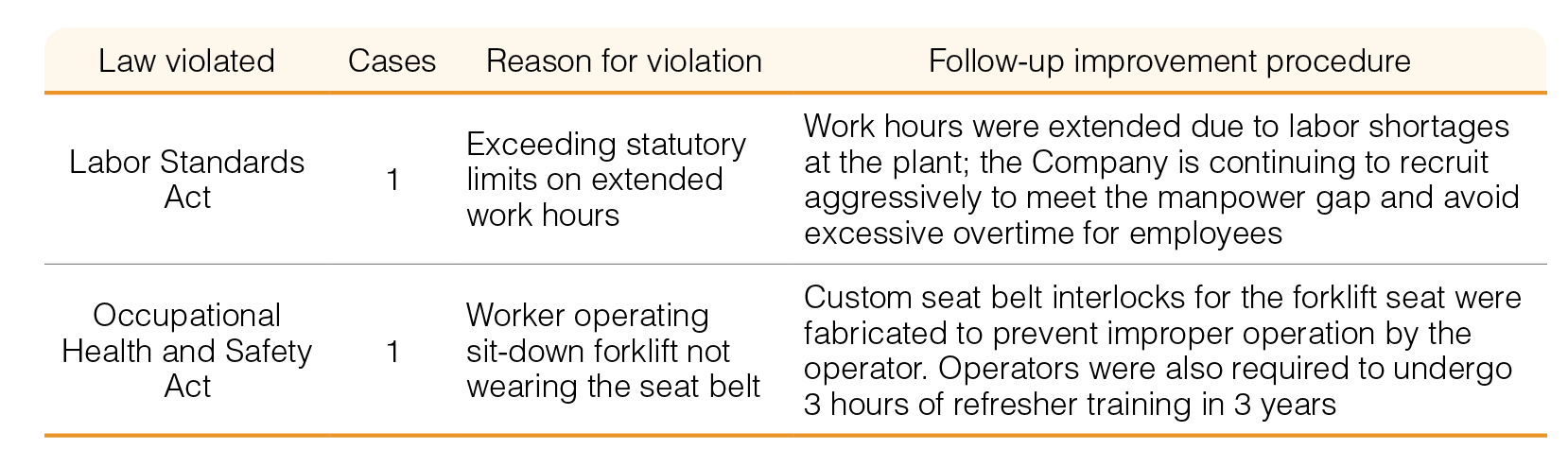

A permanent OHS contact point was established in each business group to ensure effective OHS management. The Occupational Health and Safety Committee was also set up, which is composed of the Group Operation Management Center, managers of business units, as well as labor representatives, whose the number account for more than one-third of the committee members. The OHS Committee is convened quarterly together with subsidiariesʼ OHS Committees to examine OHS management policy and matters, and to continue optimizing and managing the OHS risks at the company to ensure a safe and hygienic working environment for employees.

Composition of Occupational Health and Safety Committees

ISO 45001 Occupational Safety and Health Policy

-

Implement Cleaning Production、Pollution Prevention and keep improving on all Environmental Activities.

-

Fulfill the Obligations and Responsibility for Environment Protection and improve the Health and Safety of employees.

-

Encourage the suppliers to implement Environment Protection, Health and Safety programs.

-

Control the risks of Safety and Health in the workplace to prevent Occupational Injuries and Illnesses.

-

Monitor、Control and Reduce the Greenhouse Gases, and save the Energy and Resources continuously.

-

Consider the Life Cycle of products; improve the Recyclability and Reusability of material continuously, to achieve no banned Environment Harmful Substances in our products.

-

Declare the Responsibilities for Environment, Health and Safety to all employees, and ensure their awareness.

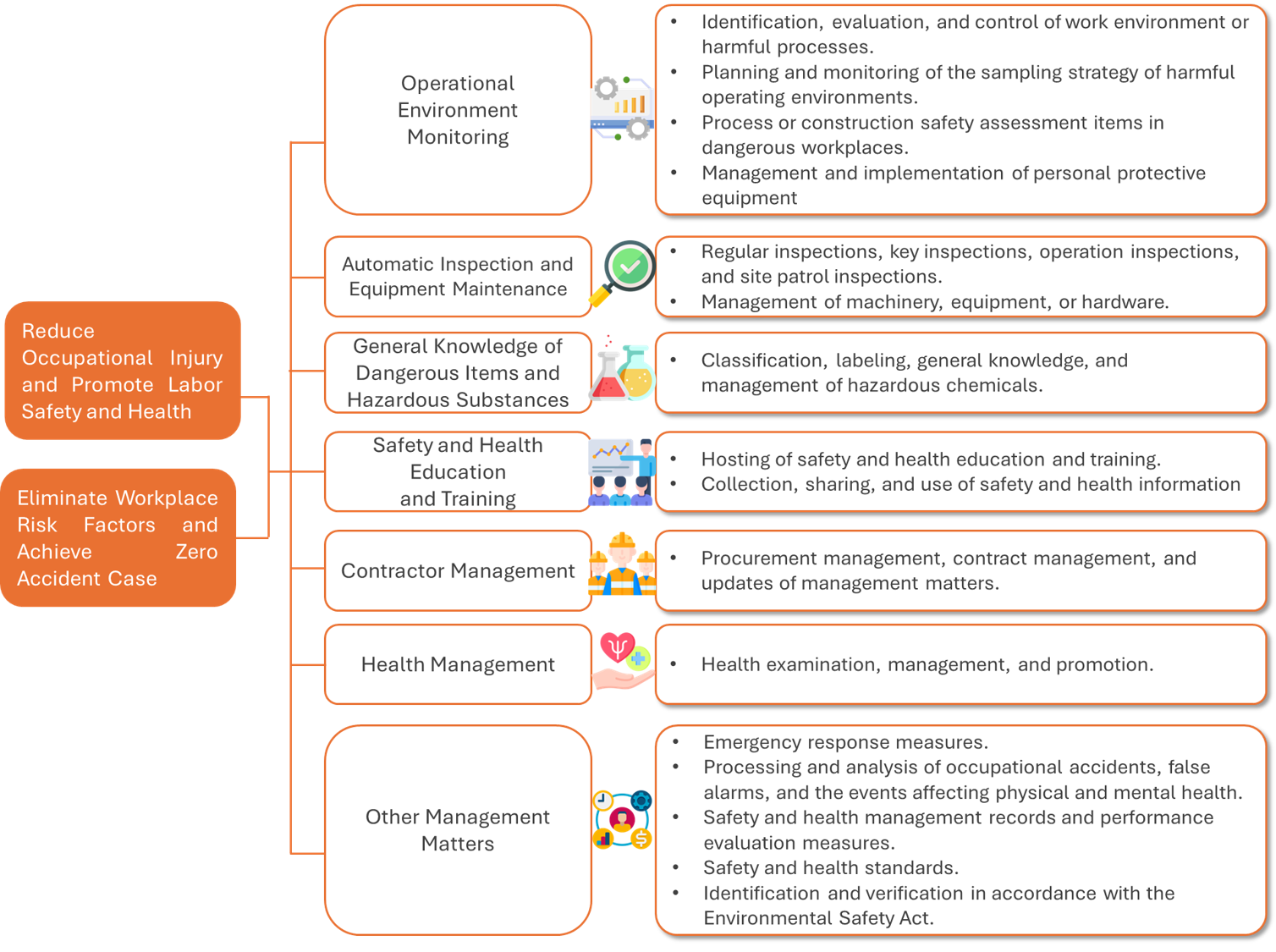

Occupational Safety and Health Management

At present, GIGABYTE’s Occupational Safety and Health Management Plan can be subdivided into 16 items, including workplace hardware testing, operating standards setting, education, and training, health promotion, disaster response, etc. Each item is reviewed and audited every year.

Occupational Safety and Health Risk Management

Comprehensive identification of occupational safety and health risks helps to detect potential hazard factors early, and annual management plans assist in controlling and eliminating the factors. GIGABYTE defines risk assessment processes, which are then periodically assessed by the OHS contact point in each business group. The assessments cover operational frequency, workflow, equipment and materials used, and operating environment. Risks are divided into 4 levels according to the assessing results. Further assessment of whether the Companyʼs current operating control procedures are sufficient to respond to the listed risks is then conducted. When necessary, a management process will be adjusted according to the identification results to prevent the occurrence of occupational accidents.

Process and Results of Occupational Safety and Health Risk Assessment

After risk identification, GIGABYTE first reviews the existing operation management process to confirm the integrity of the Companyʼs existing regulations and starts improvement of the discovered management gaps. For Level 1 high-risk cases, risk control measures such as formulation/revision of operating procedures, as well as enhanced supervision, measurement, communication, and training frequency were adopted. Those are also prioritized in health and safety targets and proposal management. We will continue to manage occupational safety and health risks through PDCA processes in order to provide employees with a safe and healthy working environment.

Incident Reporting and Handling

GIGABYTE formulates the “Incident Reporting and Handling Work Instructions” to enhance the employee reporting, recording, review, presentation, and handling procedures for occupational accidents. The “Labor Health and Safety Work Rules” were also formulated to explicitly state that employees are required to “stop work immediately if you feel that you or your colleagues are being put at risk. Only resume work after changes that will prevent harm to yourself and others have been organized.”

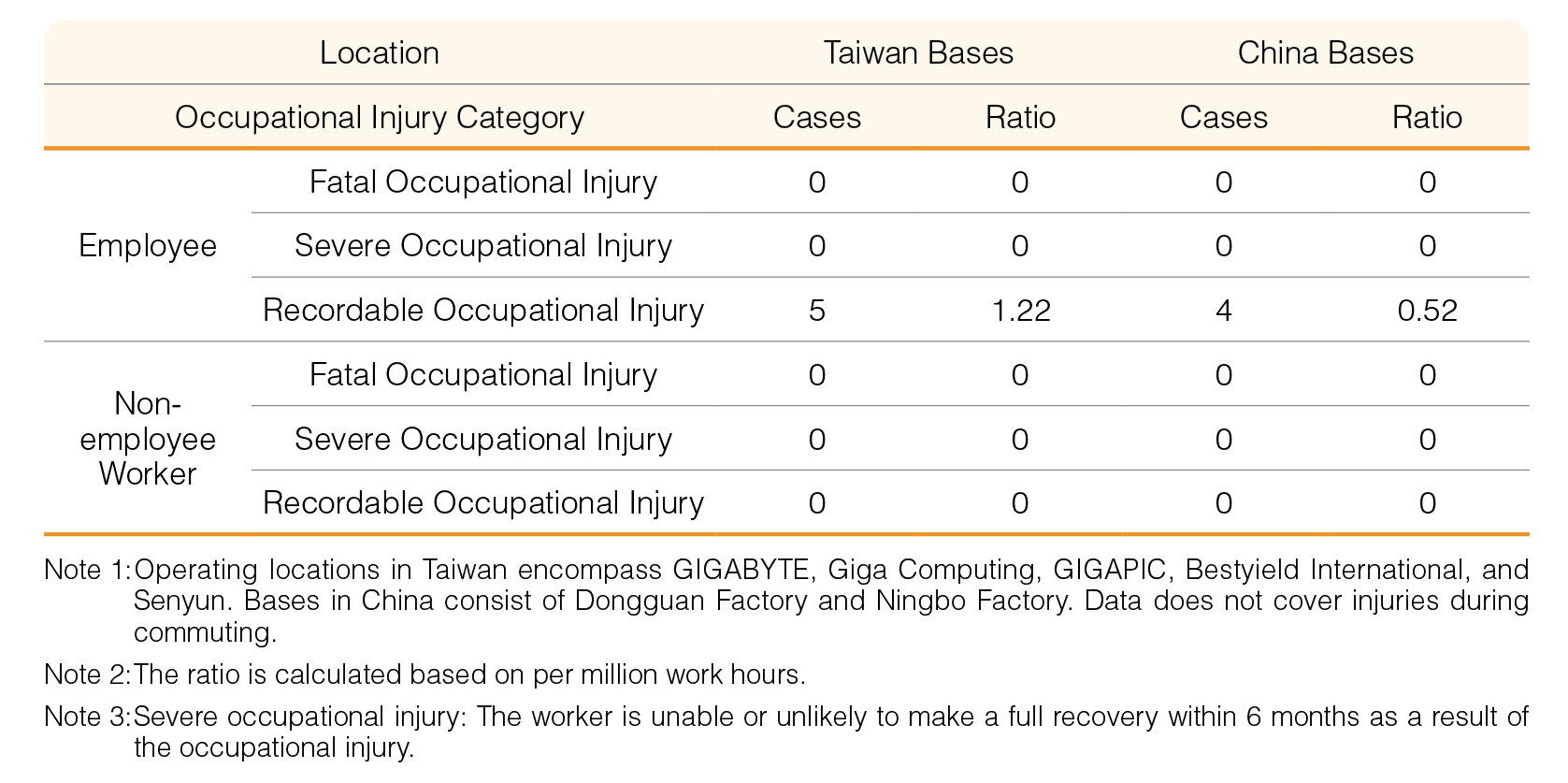

Occupational Injury and Disaster Statistics

In 2024, GIGABYTE Technology reported a total of nine occupational accidents at its Nanping and Ningbo factories. The incidents primarily involved crush or pinch injuries during operational processes. Following each incident, case summaries were promptly compiled and shared through internal awareness articles. In addition, employee training was reinforced, and the design departments were notified to implement safety improvements.

Employee Absence Rate

| Indicator | 2023 | 2024 |

|---|---|---|

| Total number of days lost | 23,409 | 14,789 |

| Total days scheduled to be worked | 1,302,448 | 1,089,688 |

| Absentee rate | 1.80 % | 1.36% |

| Data coverage (by no. of employees) | 95.43 % | 67.6% |

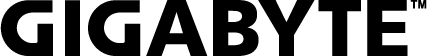

Labor infringements

There were 2 cases of labor infringements at GIGABYTE in 2024. Corrective action has now been taken on these infringements and a post-incident review carried out. In the future, we will continue to strengthen our internal OHS management to ensure that the infringements do not recur.

- Home

- Innovation Management

- The Guanxi Blue Zone

- The Ocean is Our Home

- From the Chairman

- Commitment to CSR

- Stakeholder Engagement

- Material Topics

- SDGs

- Corporate Organization

- Code of Conduct

- Information Security & Privacy

- Risk Management

- Supply Chain Management

- Tetralogy of Supply Chain Engagement

- Conflict Mineral

- Environmental Management Policy

- Brand Strategy and Business Reputation Management

- Climate Strategy and Risk Management

- Customer Relations Management

- Eco-friendly Product

- Extended Product Responsibility

- Biodiversity

- Circular Economy

- Green Action

- Sustainability/Environmental Education

- Green Activities

- Working Holiday

- Corporate Volunteering

- Go Green Taiwan

- Make Earth Green Again

- Tree Map

- Overview/Core Concept

- Rooftop Farm

- Ecology Photo Competition

- Resource Hub

- Diverse and Inclusive Workplace

- Talent Management

- Human Rights Management

- Talent Cultivation and Development

- Occupational Safety

- Health Care

- Upgrade Your Life

- Social Inclusion

- CSR Milestone

- Economic Aspect

- Environmental Aspect

- Social Aspect

- CSR Report