Since the launch of the Green Action Plan in 2009, GIGABYTE has been devoted to building employeesʼ environmental awareness in their work and life through a comprehensive and pragmatic approach. Environmental protection and sustainability should not be lofty topics but rather a kind of habit practiced every day. As for environmental performance management, GIGABYTE plans a clear long-term goal and adopts active reduction measures based on a short-term target, “333 Reduction”, aiming to reduce carbon, water, and waste by 3% per year.

The environmental performances are disclosed as below. For emissions and energy-related performance, the data boundary covers GIGABYTEʼs operation headquarters (including subsidiary Giga Computing), Taoyuan Nanping Factory, Dongguan and Ningbo Factories in mainland China, as well as the Taipei Silicon Valley Park Offices, where GIGABYTEʼs subsidiaries G-Style, Bestyield International, Selita Precision, and sub-subsidiary GIGAIPC are located. This coverage accounts for approximately 87.67% of the Groupʼs consolidated revenue in 2024. For water and waste performance, the data boundary covers GIGABYTEʼs headquarters building, Taoyuan Nanping Factory, Dongguan and Ningbo Factories in mainland China. The revenue from these sites in 2024 accounted for 77.69% of the Groupʼs consolidated revenue.

Performance of Environmental Management Target

Progress Tracker of Long-term Reduction Targets

Reduce carbon emissions by 50% in 2025 compared to 2009

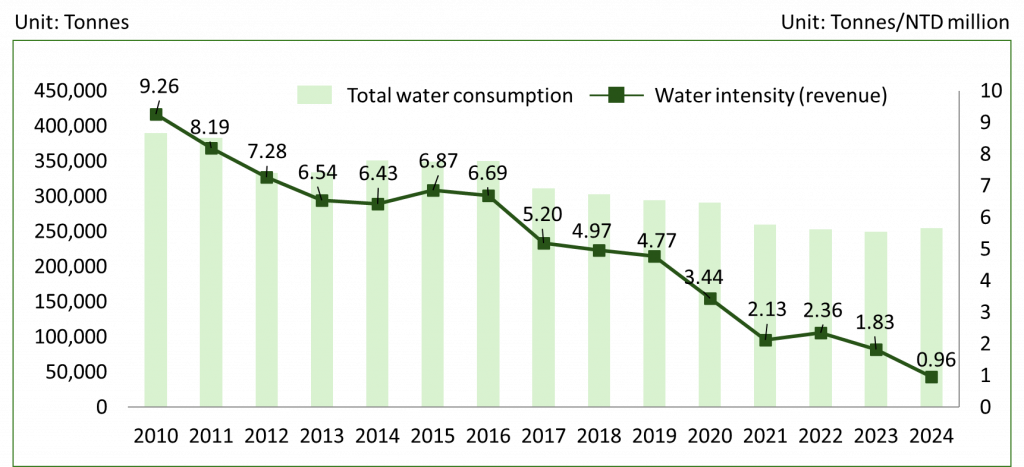

Reduce water use by 20% in 2030 compared to 2010

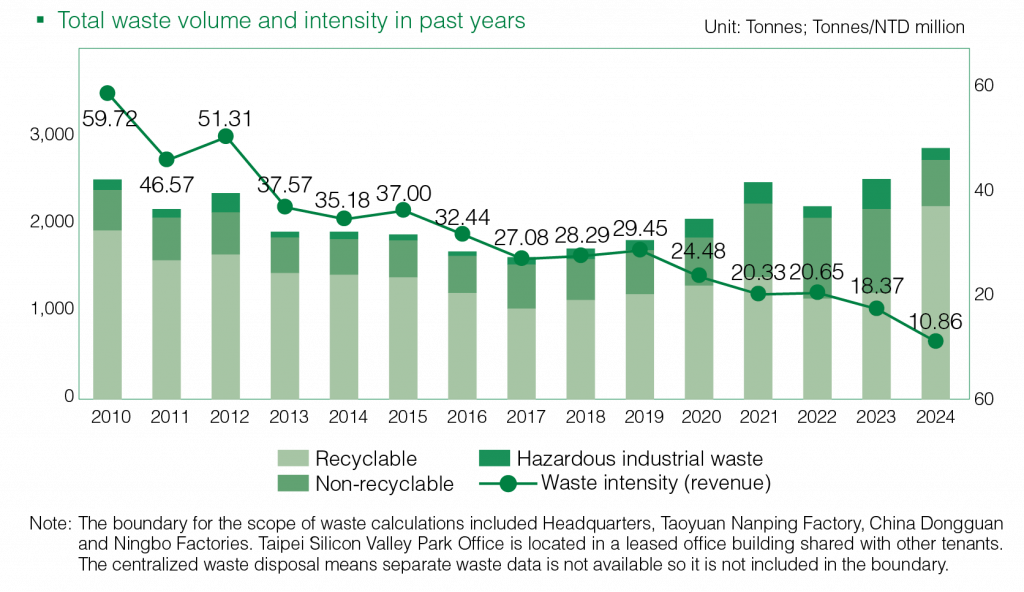

Reduce waste generation by 50% in 2030 compared to 2010

Progress Tracker of 333 Reduction Plan Targets

Reduction Performance of GHG Emissions, Water, and Waste in 2024

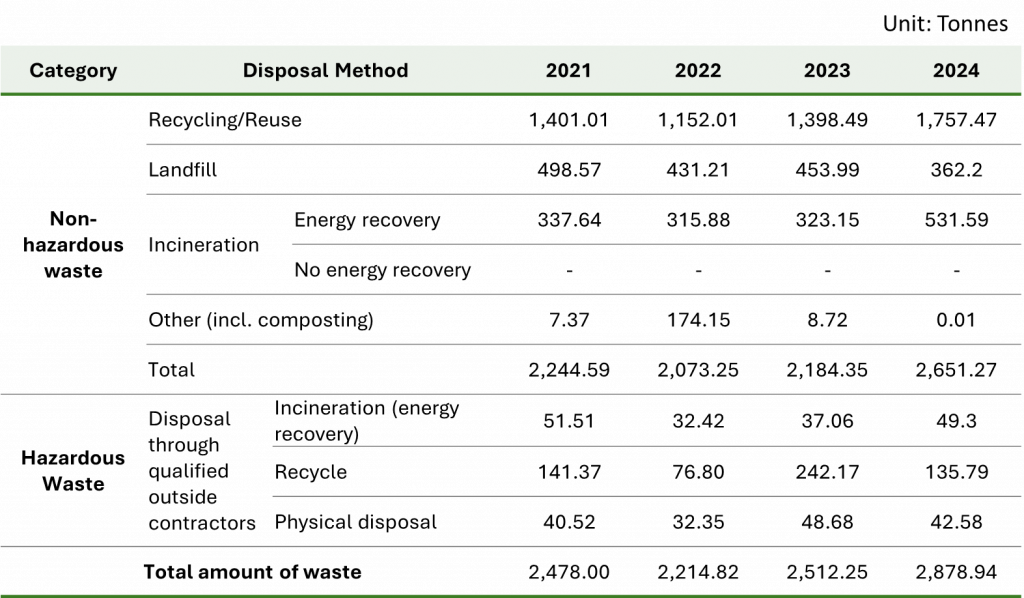

Due to the updated 2022 electricity emission factor released by Chinaʼs Ministry of Ecology and Environment and the National Bureau of Statistics on December 20, 2024, which showed a decrease, GIGABYTE achieved its goal of reducing Scope 1 and Scope 2 carbon emissions by 50% compared to the 2009 baseline ahead of schedule in 2024. However, the company did not meet its short-term and mid-to-long-term waste reduction targets. The main reason was a shift in market demand that led to an increase in server orders, resulting in higher production volumes and waste generation. Nevertheless, GIGABYTE continues to implement waste recycling and reduction initiatives. As a result, the amount of waste generated per NT$1 million in revenue decreased compared to both the previous year and the baseline year. The company will continue to review its reduction targets, promote internal waste reduction programs, and optimize resource utilization and recycling mechanisms to steadily progress toward its waste reduction goals.

Performance of Environmental Resource Management

Energy Conservation

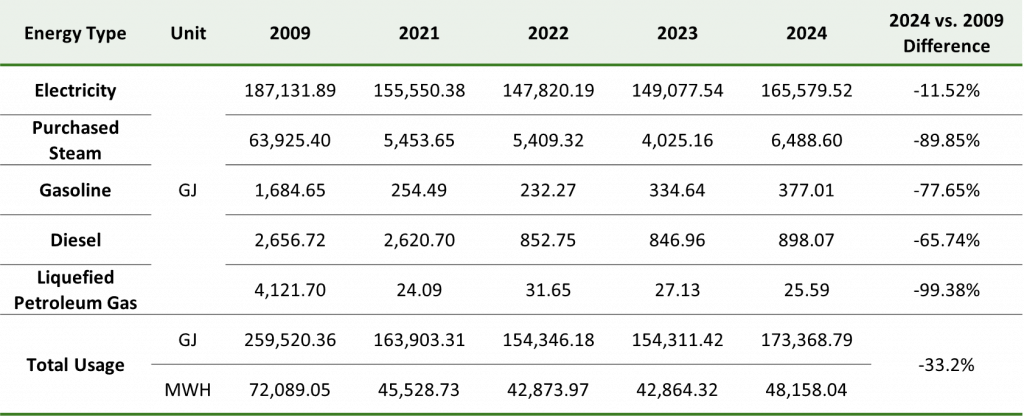

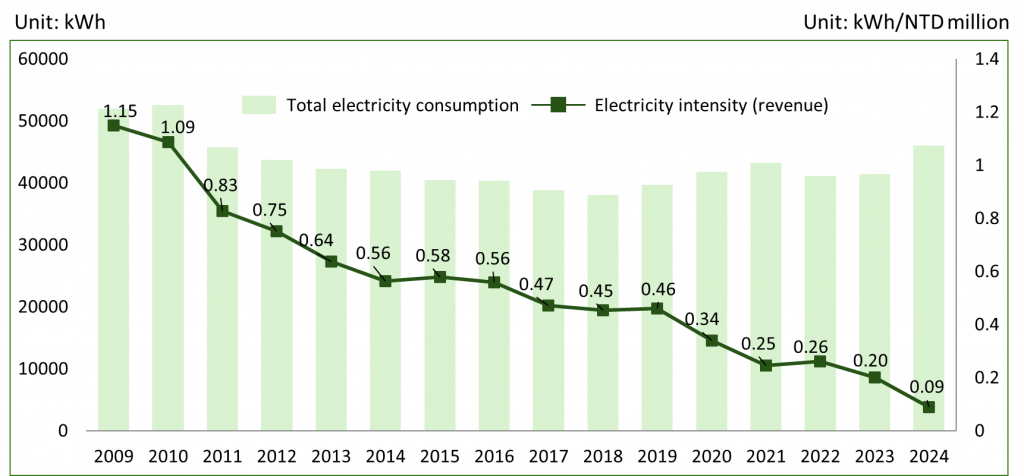

Electricity is the primary type of energy used by GIGABYTE in our routine operations and production processes. Since it is the major source of GIGABYTEʼs greenhouse gas emissions, we conduct careful data collection, inventories, and quality assurances carried out by a third party in accordance with ISO14064-1 Standards every year. Total electricity consumption in 2024 was 45,994.31 MWh, an increase of 11.1% compared to 2023 and 11.52% lower than 2009. Analysis of increase in electricity consumption found that this was due to the increased production of AI servers and more energy-intensive production processes in recent years. Total energy consumption in 2024 from electricity and other sources amounted to 173,368.79 GJ, a decrease of 33.2% compared to the base year of 2009. The intensity of total energy consumption per 1,000 pieces of production in 2024 was 15.15 GJ and per capita was 27.78 GJ.

2024 Energy Conservation and Emission Reduction Projects

| Operation Base | Energy Conservation Project | Investment Amount (NTD) | Electricity Saving (kWh) | Energy Reduction (GJ) | Annual Emission Reduction (t-CO2e) |

|---|---|---|---|---|---|

| Headquarters | Smart Electroplating Nameplate | 48,008,500 | 4,248 | 15.29 | 2,098.51 |

| Automated Testing System Platform for Electronic Gearshift Mainboard | 666.93 | 2.40 | 329.46 | ||

| Process Ice Machine Upgrade for Energy Saving | 160,199 | 576.72 | 79,138.31 | ||

|

Nanping Factory |

Introduction of Air Compression System – Adsorption Dryer | 272,086 | 979.51 | 134,410.48 | |

| Reuse of Ambient Heat from Server Testing | 82,688 | 297.68 | 40,847.87 | ||

| Dehumidifier Equipment Upgrade | 216,810 | 780.52 | 107,104.14 | ||

| Implementation of Pneumatic Arm for Server Packaging | 216.3 | 0.78 | 106.85 | ||

| Replacing Assembly Pallet Transport with LOADER RACK | 77,065 | 277.43 | 38,070.11 | ||

| Modification of Ambient Heat Supply Method for Air Conditioner Testing | 1,584 | 5.70 | 782.5 | ||

|

Dongguan Factory |

Voltage Stabilizer/Transformer (AVR) Phase-Out Project | 181,248 | 652.49 | 140,249.70 | |

| Automated Barcode Scanning for Packaging Cartons | 1,012.4 | 3.64 | 783.40 | ||

| Energy-Saving Nitrogen Generator | 107,500 | 387.00 | 83,183.50 | ||

| Grade 1 Energy-Efficient Air Compressor | 129,131 | 464.87 | 99,921.57 | ||

| Installation of Grade 1 Energy-Efficient Heat Pump in Employee Dormitory | 5,760 | 20.74 | 4,457.09 | ||

|

Ningbo Factory |

Corner Sealing Carton Machine | 6,052.8 | 21.79 | 4,662.47 |

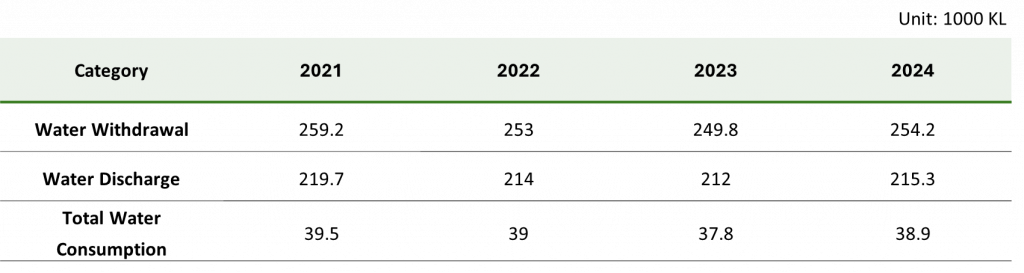

Water Resource Conservation

The manufacturing process of GIGABYTEʼs products is mainly assembly, which only consumes a little water, and the water sources for basic factory facilities and domestic water are tap water. The water resources management policies are promoted and implemented through water-saving policies, education promotion, and annual performance reporting. In addition, the G-HOME Sustainable Eco-Roof at the Headquarters is equipped with rainwater recycling systems that can supply about half the water for irrigation each year. Both Dongguan Factory and Ningbo Factory in China have established water recycling systems for their air-conditioning and manufacturing facilities. In the future, we will continue to look for raw materials with lower water footprints to achieve the water-saving target of the overall product lifecycle.

Regarding wastewater discharge, all of GIGABYTEʼs wastewater is domestic sewage and is legally discharged into underground sewers in compliance with local laws and regulations. Thus, it has not caused impacts on the environment and ecology around the business locations.

2023 Water Conservation Projects

|

Operation Base |

Water Conservation Project |

Investment Amount (NTD) |

Annual Emission Reduction (t-CO2e) |

|---|---|---|---|

| Nanping Factory | Install water-saving connectors on faucets | 2,240 | 1,800 |

Waste Reduction and Pollution Control

The domestic waste, recyclable waste, and hazardous industrial waste generated by each GIGABYTEʼs operating base are entrusted to local qualified manufacturers for disposal. In accordance with local waste disposal regulations, the manufacturer clears and transports waste off-site for disposal, and provides a proper disposal receipt for the companyʼs declaration and management of disposal. Audits are also conducted regularly at waste disposal manufacturers to ensure proper waste disposal. We strive to reduce waste by improving the process and introducing circular resource modes. Our ultimate goal is to achieve “Zero Waste and Zero Pollution”.

2024 Waste Reduction Projects

|

Operation Base |

Waste Redcution Project |

Investment Amount (NTD) |

Redcution Target |

Annual Waste Reduction (metric tons) |

|---|---|---|---|---|

|

Nanping Factory |

Replacement of SFIS stickers with engraving equipment | 915,000 | Label | 0.004 |

| Replacing paper SOPs with digital screens | Paper | 0.322 | ||

| Reducing Tin slag ratio | Tin slag | 1.7 | ||

| Introducing online production for film coating | Plastic Packaging | 0.019 | ||

| Simplifying origin labeling | Label | 0.142 |

VOCs Management

Volatile Organic Compounds (VOCs) can easily react with other pollutants in the lower atmosphere, such as photochemical reactions with nitrogen oxides (NOx) to form ozone or smog, one of the main causes of poor air quality. GIGABYTEʼs air pollution control complies with Taiwan and mainland China regulations and standards. Taoyuan Nanping plant is not subject to Taiwanʼs “Air Pollution Control Act” at present. Dongguan and Ningbo Factories have been inspecting VOCs every year since 2020 in order to properly solve the problem of xylene and non-methane total hydrocarbon emissions. In 2024, there were no emissions from the Dongguan factory. The monitoring value at the Ningbo factory was 1.263 metric tons, and all emissions complied with regulatory standards. The emissions comply with local regulations and standards.

VOCs Emissions

[Note] Before 2020, only China Dongguan Factory inspected VOCs emissions.

Sustainability and Environmental Education Promotion

Over the past decade, the Green Action Plan has delivered a variety of services: knowledge-oriented activities such as seminars, workshops, and newcomer training; experience-oriented activities such as working holidays, a green volunteering club, drawing and photography contests; custom-oriented measures like vegetarian food promotion, waste reduction – which have effectively promoted employees to develop more sustainable lifestyles and cultivate their environmental protection concepts; call on suppliers of “Reduction. Sharing. Love the Earth” Alliance to join the “333 Reduction Plan” and environmental protection activities to guard the planet together.

For further details, please refer to Sustainability and Environmental Education.

For further details, please refer to Tetralogy of Supply Chain Engagement.

Besides the internal environmental education, the G-HOME GIGABYTE Sustainable Eco-Roof, founded in 2013, also promotes the benefits of rooftop greening by opening it to external visitors. Between 2017 and 2022, G-HOME received the Environmental Education Facility and Field Certification from the Environmental Protection Administration. The two certificated environmental education courses, Rooftop Greening is not A Dream and The World is a Circle, are developed to promote the concepts of sustainability, co-prosperity, and zero waste to the public, industries, government, and academia. Moreover, we look forward to seeing more sustainable eco-roofs being constructed to make Taiwan greener and healthier.

Sustainability and Environmental Education Hours in the Recent 5 Years

- Home

- Innovation Management

- The Guanxi Blue Zone

- The Ocean is Our Home

- From the Chairman

- Commitment to CSR

- Stakeholder Engagement

- Material Topics

- SDGs

- Corporate Organization

- Code of Conduct

- Information Security & Privacy

- Risk Management

- Supply Chain Management

- Tetralogy of Supply Chain Engagement

- Conflict Mineral

- Environmental Management Policy

- Brand Strategy and Business Reputation Management

- Climate Strategy and Risk Management

- Customer Relations Management

- Eco-friendly Product

- Extended Product Responsibility

- Biodiversity

- Circular Economy

- Green Action

- Sustainability/Environmental Education

- Green Activities

- Working Holiday

- Corporate Volunteering

- Go Green Taiwan

- Make Earth Green Again

- Tree Map

- Overview/Core Concept

- Rooftop Farm

- Ecology Photo Competition

- Resource Hub

- Diverse and Inclusive Workplace

- Talent Management

- Human Rights Management

- Talent Cultivation and Development

- Occupational Safety

- Health Care

- Upgrade Your Life

- Social Inclusion

- CSR Milestone

- Economic Aspect

- Environmental Aspect

- Social Aspect

- CSR Report